Electric motors are very useful machines and are used to operate pretty much every electronic device we use, from power tools to vacuum cleaners and blenders. However, these motors use electricity and generate heat, which means that they can break down and cause the device to malfunction.

While you can offset most of these situations by following the users’ manual, there are some situations where you simply have no way of preventing a breakdown. Fortunately, most of these breakdowns aren’t complete, and your electric motor can be repaired. Here are some of the most common reasons why electric motors burn out.

Vibrations

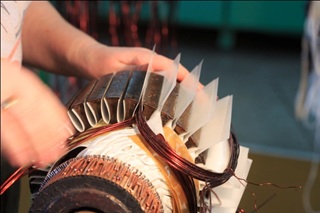

Most electric motors are insulated against vibration because it has a negative impact on their performance, and can ultimately cause it to break down. The most common way vibration impacts the performance of electric motors is by stripping away electrical insulation of the windings. When that happens, your windings can short out and burn out the whole motor.

Age

Over time, parts of the electric motor can deteriorate and start underperforming or causing a breakdown. It is possible to offset these problems if you maintain your motor regularly and change the worn parts to prolong the life of your motor.

For instance, the insulation of the windings is typically just nonconductive and heat resistant lacquer. However good this lacquer is at insulating the windings, over time and due to other factors it can deteriorate and cause you major problems.

Heat

Electrical current tends to generate a lot of heat. If you have ever used any device with an electric motor for an extended period of time, you have surely noticed how hot it gets. Even though the heat itself doesn’t affect the performance of the motor itself, it can warp, melt or otherwise damage any part of the motor, causing it to malfunction.

The part which is the most sensitive to heat is, again, the insulation on the winding which can melt and then short out the motor like in previous two entries. However, other parts can also be affected by the heat, including the wires and the cooling fan.

Mechanical Damage

This one goes without saying, but any mechanical damage risks causing your motor to break down. Electric motors are for the most part very delicate and fine-tuned machines. If some parts are moved or dented even a little bit, it can cause misbalance with potentially catastrophic consequences to your electric motor.

Dirt and Debris

A lot of electric motors work in less than ideal environments. For instance, your vacuum cleaner is constantly exposed to dust, your blender can be saturated with cooking oil and food pieces, while your power tools can collect any kind of debris like metal, wood or other materials.

In order to keep them functioning normally, you should take precaution and prevent as much of this as possible.

Overloading

If the motor is overloaded with current much higher than it is designed to support, it may overheat and cause all sorts of problems inside your motor, ranging from melting parts of the motor to smoking and even catching fire.

On the other side of this spectrum, if you supply the current which is too low voltage and you put too much strain on the motor, you are creating a perfect storm of bad conditions for your motor. It will attempt to draw more electricity from the power supply and overload itself.

Making sure that your electric motor has a long and successful life is a lot easier than you may thing, as long as you are willing to adopt some positive behaviors and take a bit more care with them.